With the improvement of people’s living standards, more people have higher requirements on the precision of flour. Therefore, flour mills are trying to improve the precision and quality of flour. Linear screens are increasingly favored by flour processing enterprises.

The processing precision of flour is mainly measured by the bran star content of flour. The whiter the pink, the less the content of bran star, the higher the precision of flour. The processing precision of flour is affected by many factors such as raw grain, processing technology and operation index. Higher requirements were placed on the screening of wheat and the precision of flour particle size screening. After milling, the wheat needs to be selected using a flour sifter. The main purpose is to increase the powder yield during the milling process, and the endosperm on the cortex should be scraped as much as possible.

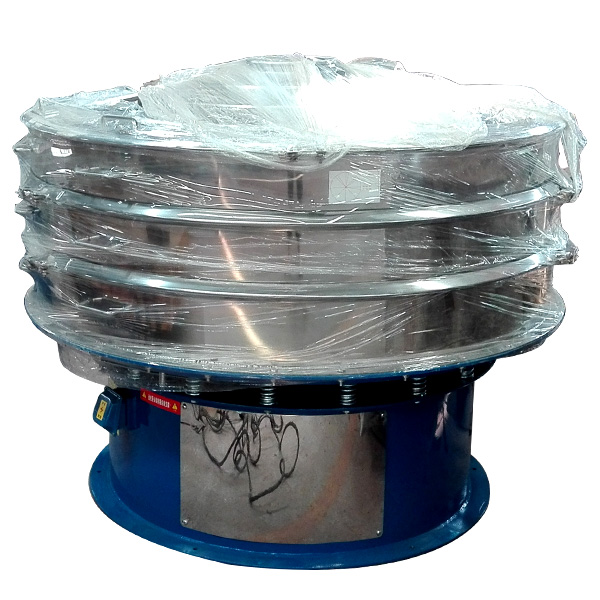

In the scraping process, a small amount of wheat husks is broken into fine powder, which needs to be filtered to enter the flour to improve the particle uniformity of the flour. In this production process, it is necessary to use a flour sifter to screen it for improving the fineness of the flour.

The linear screen produced by Jinte is simple, compact and easy to maintain. It adopts a fully enclosed structure to prevent flour dust from flying, low noise, and quiet and environmental protection. The large flow discharge port is at the bottom to facilitate the installation of equipment for assembly line operations. The upper discharge port can be arbitrarily adjusted within 360° for easy installation and use. Large processing capacity, high screening accuracy, energy saving, can achieve twice the result with half the effort. The new grid structure, the network has high tension and long service life, and the user can quickly change the screen.

In the more scale flour production line, the straight-line screen improves the precision of the product with high-efficiency filter screening, solves the problem that the classified materials are easy to block the net, and the direct discharge type discharge is efficient and rapid, which reduces the labor intensity of the staff. To avoid the return of a large number of unqualified products and reduce production costs.

Henan Jinte Vibration Machinery Co.,Ltd has developed into a medium and large international enterprises which specialize in designing and producing screening equipment, vibration equipment and conveying products for complete sets of sand and gravel production lines.

We have professional R&D teams. If u have any concern about equipment, please donot hesitate to contact us. Here is our website site: https://www.hnjinte.com

WhatsApp: 15090360573

Skype:HU2399463374@gmail.com

E-mail: jintejixie@yeah.net

TEL: +86 18037396988

Post time: Oct-14-2019