LS (GX) Type Flexible Screw Conveyor to Transfer

Flexible Screw Conveyor

Introduction:

GX spiral conveyor is the earliest Conveyor Machine in China.

The Screw Conveyor uses the rotation of the screw to move the material along the shell to achieve the purpose of transportation. The force that prevents the material from rotating with the screw is the weight of the material and the friction of the shell.

Advantages

If u wanna know the difference between Screw Conveyor and Belt Conveyor, please click: https://www.hnjinte.com/news/screw-conveyor-vs-belt-conveyor

working principle and structure:

The screw conveyor usually consists of three parts: the body of the screw machine, the inlet and outlet device, and the drive device. The company does not supply electrical switch and motor starting equipment.

The body of the screw machine is composed of the head section, middle section and tail section. Generally speaking, in the final assembly, the middle section is arranged in order of length, the longest section is near the head section, and the middle section of the same length is next to each other. If there are special requirements, the middle section will be arranged in order when ordering.

The thrust bearing is installed in the head section to bear the axial force, and the spiral shaft is supported by the bearing in the middle section and the tail section. In addition, the shaft section is equipped with radial bearings which can be moved in an axial direction to compensate for the error of the length of the screw shaft and adapt to the change of temperature. The form of spiral surface has solid spiral (S method) and band spiral (D method) two kinds. Each screw shaft is connected by flange, which ensures the interchangeability of the connecting shaft and facilitates maintenance.

The cover is tile-type and clamped on the shell with the cover buckle. If the sealing performance needs to be improved, users can add waterproof canvas between the cover and the shell by themselves.

There are four kinds of feeding port, square feeding port, hand push feeding port and rack feeding port. The user opens and welds the body in the field. When arranging the position of the inlet and outlet, the distance from the inlet to the end should be ensured, and the collision between the inlet and the loading cup of the bearing, the connecting flange of the housing and the base should be avoided.

Technical Parameter:

|

Item |

Unit |

Data |

||||||||

|

Screw diameter |

mm |

150 |

200 |

250 |

300 |

400 |

500 |

600 |

||

|

Maximum production capacity |

Carbon toner |

Screw speed |

rpm |

190 |

150 |

150 |

120 |

120 |

90 |

90 |

|

Delivery volume |

t/h |

4.5 |

8.5 |

16.5 |

23.3 |

54 |

79 |

139 |

||

|

Cement |

Screw speed |

rpm |

90 |

75 |

75 |

60 |

60 |

60 |

45 |

|

|

Delivery volume |

t/h |

4.1 |

7.9 |

15.6 |

21.2 |

51 |

84.8 |

134.2 |

||

|

Raw material |

Spiral speed |

rpm |

75 |

75 |

75 |

60 |

60 |

60 |

50 |

|

|

Delivery volume |

t/h |

3.1 |

7.6 |

13.8 |

18.7 |

45 |

93.3 |

129 |

||

|

Screw speed range |

rpm |

20、30、35、45、60、90、120、150、190 |

||||||||

|

Drive assembly |

|

We produce two kinds of YJ and YTC, which can be selected by users |

||||||||

Note:

1. N -- speed r/min (deviation is allowed within 10%)

2, Q - throughput m3 / h (the throughput is calculated when filling coefficient bits = 0.35)

Factory & Team

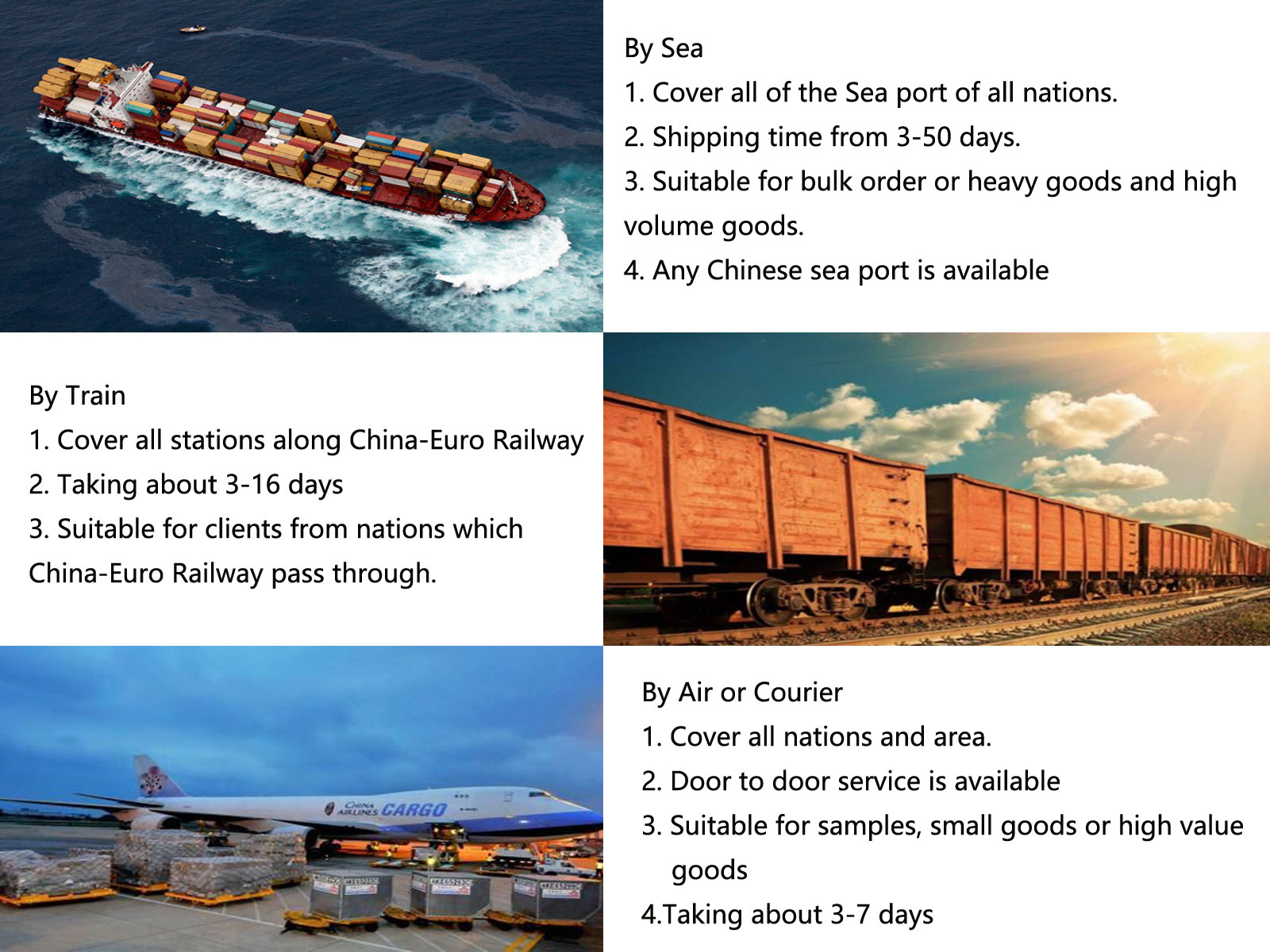

Delivery

√ Since our factory belongs to the machinery industry, the equipment needs to be matched with the process.

The size, model and specifications of the product can be customized according to customer needs.

√ All products in this store are for virtual quotes and are for reference only.

The actual quotation is subject to the technical parameters and special requirements given by the customer.

√ Provide product drawing, manufacturing process and other technical services.

1. Can you offer the customized solution to my case?

Our company has a professional R & D team, and be able to customize mechanical products for you according to your needs. At the same time, our company guarantees that every product produced for you is in compliance with the national and industry standard, and no quality problems.

Please send us inquiry if u have any concerns.

2. Is the machine produced safe and reliable?

Absolutely yes. We are a company specializing in the production of machinery. We have advanced technology, excellent R & D team, superb process design and other advantages. Please believe that we can fully meet your expectations. The machines produced are in line with national and industry quality standards. Please feel free to use.

3. What is the price of the product?

The price is determined by the specifications of the product, the material, and the special requirements of the customer.

Quotation method: EXW, FOB, CIF, ect.

Payment method: T/T, L/C, ect.

Our company is committed to selling high quality products that meet your requirements at an acceptable price.

4. Why do I trade with your company?

1. Reasonable price and exquisite workmanship.

2. Professional customization, good reputation.

3. Carefree after-sales service.

4. Provide product drawing, manufacturing process and other technical services.

5. Case experience of working with many outstanding domestic and foreign companies over the years.

Regardless of whether a deal is reached or not, we sincerely welcome your letter. Learn from each other and make progress together. Maybe we can be friends of the other side. ![]()

5. Are you engineers available for overseas installation and training matters?

At the client’s request, Jinte can provide installation Technicians to supervise and assist in the assembly and commissioning of the equipment. And all the costs during the mission needs to be covered from you.

TEL: +86 18037396988

E-mail: jintejixie@yeah.net